25

Jul

Sustainable Steel: A Green Revolution in Manufacturing

The global push towards sustainability has permeated various industries, and steel manufacturing is no exception. In recent…

23

Jul

Safety and Health in the Steel Industry

In the world of Indian steel industry, steel manufacturers in Bangalore are pioneering new approaches towards safety…

20

Jul

TMT Bar Certification: Understanding Quality Standards

In the dynamic landscape of construction and infrastructure development, TMT bars play a pivotal role. With increasing…

19

Jul

What Are Some Interesting Facts About A-ONE?

In India’s steel industry, A-One Steel Group leads the way with innovation and sets current standards. Discover…

17

Jul

Choosing the Ideal TMT Bar for Your Residential Construction

Selecting the right TMT bar for your residential construction project is of paramount importance. TMT bars, or…

29

Jun

Nano Coating Technology: Elevating Steel Bars’ Corrosion Resistance

Steel is the backbone of modern construction. It’s quality plays a pivotal role in ensuring the longevity…

29

Jun

Different Grades of TMT Bars Used for Construction

TMT (Thermo-Mechanically Treated) bars are an essential component in the construction industry. They are widely used in…

28

Jun

Exploring the Life Cycle of Steel: From Factory to Future

Steel is one of the most versatile and widely used materials in the world. With an extensive…

24

Jun

TMT Bars & Earthquake Resistance

TMT bars, also known as Thermo-Mechanically Treated bars, have become an essential component of construction in recent…

21

Jun

How Steel is Made in a Factory?

Steel is one of the most widely used materials in the world, with applications in construction, transportation,…

21

Oct

What Is TMT Bars? Types of TMT Bars and Their Advantages and Prices

In the world of construction, the choice of materials plays a major role in determining the strength…

19

Feb

A-One Steel Group: On a journey to claim the Quality TMT Manufacturer Award!

A-One Steel Group, the leading steel manufacturer in South India, has been in the business for more.

12

Feb

Exclusive: Get access to the best TMT steel weight chart here

Let us start with a fundamental question – what essential factors to account for while buying TMT…

24

Jan

Impact of Structural Steel in Construction Industry

What exactly is structural steel? Is it a steel product? Is it a type of steel grade.

24

Jan

All about Hot Rolled Steel in a nutshell

According to the World Steel Association, over 3,500 different grades (basis composition, shape, and size) of steel.

24

Jan

Know Your Product: One of the most commonly used metals Steel-Pipes-Tubes

Steel remains the number one choice for scientists and engineers to take its properties a notch up.

04

Dec

Why TMT Steel Bars are the first choice for construction projects?

Thermo Mechanically Treated Bars or TMT Bars are pivotal in the construction and infrastructure industry.

05

Nov

A-One Steel Group: Embarking on a Sustainable Journey

Slowly and gradually, the resources of the earth are depleting. And this is the biggest challenge of.

10

Aug

Why use steel in Construction & Infrastructure

The world is becoming more and more sustainable every day. Considering this approach and observing prevalent...

02

Jul

Why choose A-One Steel Group

A-One Steel Group is the leading steel manufacturer in South India. Here are some of the reasons.

08

Dec

Impact Of COVID-19 On Manufacturing Industries

As India also implements work from home to find the breadth of COVID-19...

06

Dec

Steel: All You Need To Know About Steel

Steel which is an alloy of iron and carbon contains less than 2% carbon and 1% Manganese..

17

Jun

How Is Quenched Steel & Tempered Steel Made?

Difference between Quenched and Tempered Steel Quenched or tempered Steel is Steel of high strength and abrasion-free.…

12

May

Top 5 Steel-Producing Countries

The production and the import and export of steel are very crucial for a country’s economy. Nexus.

01

Nov

HISTORY OF STEEL – Steel Environment and the Future

Factories and pollution go hand in hand. As steel industries sprang across the world, pollution levels began…

01

Nov

HISTORY OF STEEL – Rise of Stainless Steel

In 1912, Harry Brearly, a British metallurgist, while experimenting with chromium, found that a layer of that…

31

Oct

HISTORY OF STEEL – Steel in War

Charles Schwab, president of the United States Steel Corporation, was now president of another company called Bethlehem…

31

Oct

HISTORY OF STEEL – The Journey to Modern Steel

Little did the world know that a new steelmaking technology was poised to revolutionise the steel industry.…

30

Oct

HISTORY OF STEEL – Steel in the United States of America

USA Steel History in the making There were vast untapped resources of iron in the West. The…

28

Oct

HISTORY OF STEEL – The Huntsman and Bessemer Breakthroughs

Two breakthroughs in Europe put the continent on the map of steel production. England was never the…

26

Oct

HISTORY OF STEEL – Blast Furnaces, Pig Iron, & Coal

Europe was experiencing an iron boom, thanks to the invention of blast furnaces. The hourglass-shaped contraption was…

26

Oct

HISTORY OF STEEL – Swords Around the World

Gone were the days of the ancient iron and steel weapons. Fast forward to the age of…

25

Oct

HISTORY OF STEEL – Metal from the Sky

Believe it or not, the first pieces of iron found on Earth actually fell from the sky!…

25

Oct

HISTORY OF STEEL – Making of the First Steel

Steel, as we know it, is widely used to build skyscrapers, bridges, and other infrastructure. But there…

30

Jun

5 Ways to Deal with Cost Overrunning in Projects

Keeping truly altruistic projects aside, every project is initiated with the final goal of gaining profit. This…

25

Jun

A-One Gold TMT Bars: Choice of Civil Contractors in Bangalore

Bangalore, the capital of Karnataka, is one of India’s most progressive and developed cities. Fondly referred to…

15

Jun

Different Types of Steel Used for Construction in Karnataka

Steel is known to be a vital ingredient used in construction, in fact, the most robust when…

13

Jun

Cost Control Techniques Every Civil Contractor in Bengaluru and Beyond Must Know

A crucial aspect of managing any construction project—be it small scale or large scale—involves the planning and…

08

Jun

How to Calculate Labor Cost for Your Construction Project in Bangalore?

No construction is ever possible without labors. Even the majestic Taj Mahal was only possible after 20,000…

03

Jun

Steel Industry in Karnataka: Challenges, Opportunities and What the Future Holds

Karnataka is one of the richest states in India when it comes to mineral resources. A leading…

31

May

How Karnataka Based A-One Steel Group Is Redefining South India’s Steel Landscape

The last few years have seen the Indian steel sector facing many problems. Despite the hardships, India…

28

May

What It Takes to Deliver the Quality Steel Products in Karnataka

When it comes to mineral resources, Karnataka reigns supreme. One of the leading industrialized states of India,…

24

May

Factors Fuelling Steel Demand in Bangalore and the Rest of the Country

Since its independence, India has seen an unprecedented growth in infrastructure and energy usage. It has made…

20

May

Buying a Home? Here’s How You Can Determine Its Construction Quality

Planning to buy a home can give you sleepless nights as it involves the examination of a…

16

May

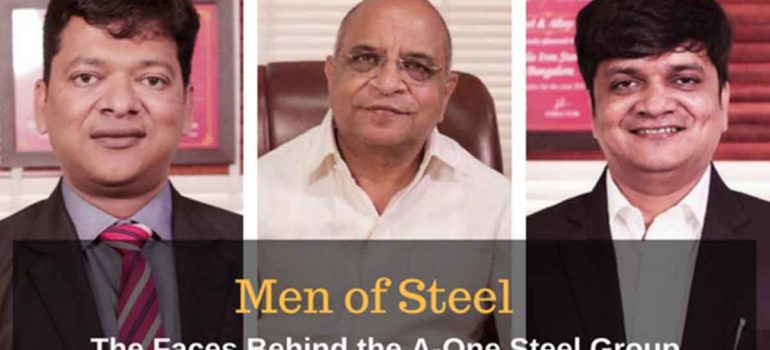

Men of Steel: The Faces Behind the A-One Steel Group

It is often said that the quality of things starts with the smallest of ideas. The same…

13

May

What Are MS Billets? How Are They Different from MS Ingot? Why A-One MS Billets?

MS Billets are semi-finished products used to roll mills for construction of long products like wire rods.…

10

May

What Is the Difference Between TMT, HYSD, and TOR Steel Bars?

Difference Between TMT, HYSD, and TOR Steel Bars TMT: Thermo Mechanically Treated or TMT bars are high-strength…

07

May

Here’s All You Need to Know About MS Structural Steel

Mild Steel (MS), also known as ‘low carbon steel’, is a type of carbon steel with a…

03

May

5 Things to Keep in Mind While Choosing TMT Bars

Let’s face it, all of us at some point in our life has dreamt of owning our…

30

Apr

How does A-One Steel Group Maintain High Quality of its Steel Products?

A-One Steel Group, one of the premier manufacturing firms in the country, has been able to leave…

27

Apr

How A-One Steel Group Ensures the Quality Customer Experience

As a customer-driven organization, A-One Steel Group strives to develop new products to meet the emerging needs…

22

Apr

Rashtra Nirman Mein Samarpit – A Commitment to the Nation’s Development

“Rashtra Nirman Mein Samarpit,” the motto of A-One Steel Group, means “A Commitment to the Nation’s Development.”…

17

Apr

How Are TMT Bars Manufactured [Step-By-Step Process Description]

Before we answer the question of how TMT bars are manufactured, let’s first know what TMT bars…

13

Apr

9 Reasons Why You Must Choose A-One Gold TMT Bars for Your Needs

Building a home is one of the most crucial decisions in your life as it requires a…

10

Apr

A-One Steel Group

A-One Steel Group Established to serve the Nation with excellent quality steel products, A-One Steel Group seeks to…